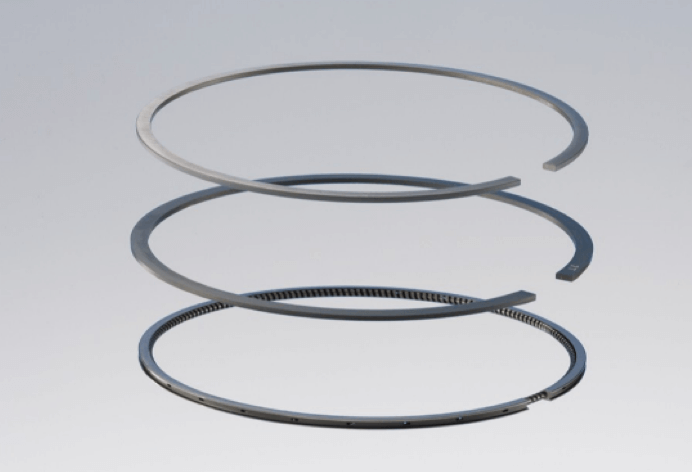

Function:

- Positioned at the top of the piston, the top ring seals the combustion chamber from the crankcase to prevent gas leaks (“blow by”)

- Transfer of heat between piston and cylinder liner

- Maintain a lubricating oil film at the cylinder liner wall to prevent abrasive scuffing

Features:

- Steel or cast iron material available

- Chrome, Nitride, PVD or DLC coating

- Suitable for Gasoline and Diesel engines in the automotive, heavy duty and marine sector