Function:

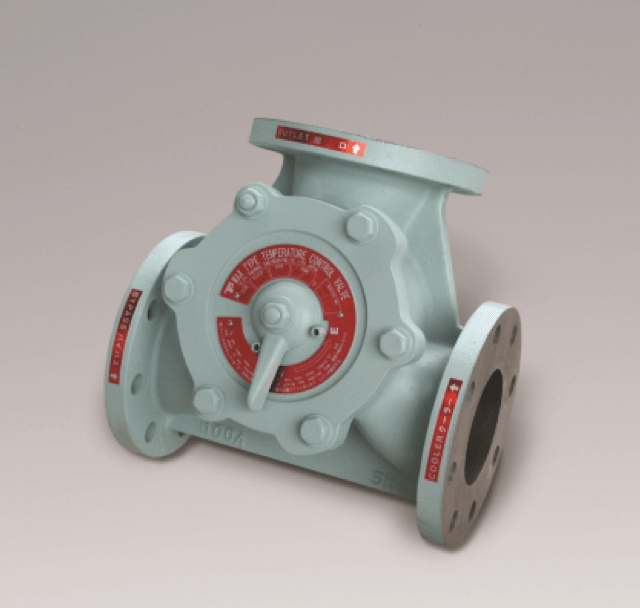

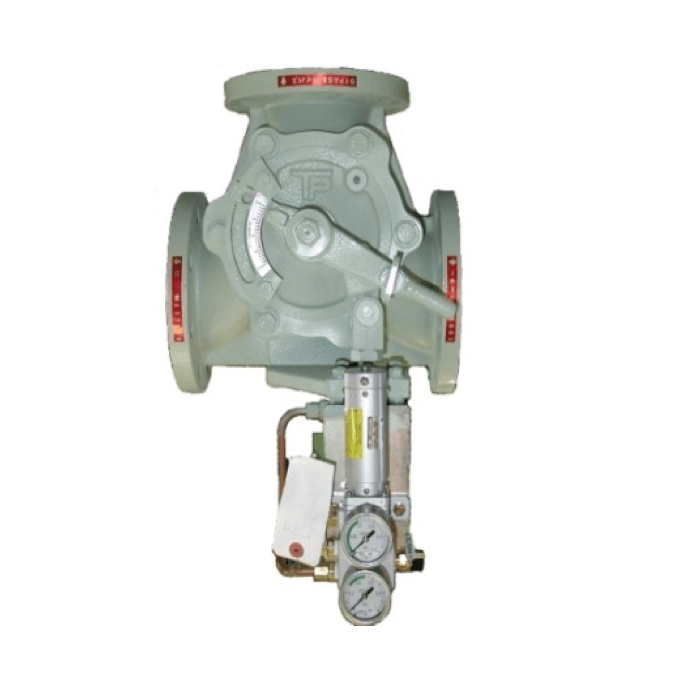

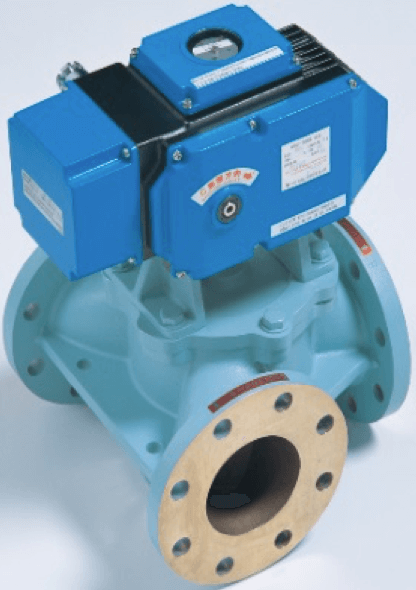

- Thermostatic temperature control valves (TCVs) mix or divert liquids depending on their temperature

- Large diesel engines in ships, power plants and cogeneration systems rely on TCVs for cooling and lubrication circuits

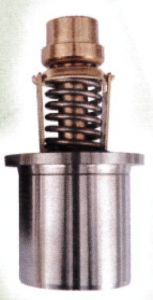

- Wax type TCVs operate with an expansive wax element – a capsule containing a filler, which expands when reaching the preset temperature

- The expansion or decompression of the wax element will open or close the valve accordingly

Features:

- No electricity or other power source is necessary – automatic and reliable operation

- Engineered to minimize cavitation and wear

- Light weight and easy maintenance

- Various sizes and temperature ranges available

- TPR valves are trusted by OE engines manufacturers worldwide